Item Info

Source: Automobile Reference Collection

Notes:

The Tire Rate Book

p. 27

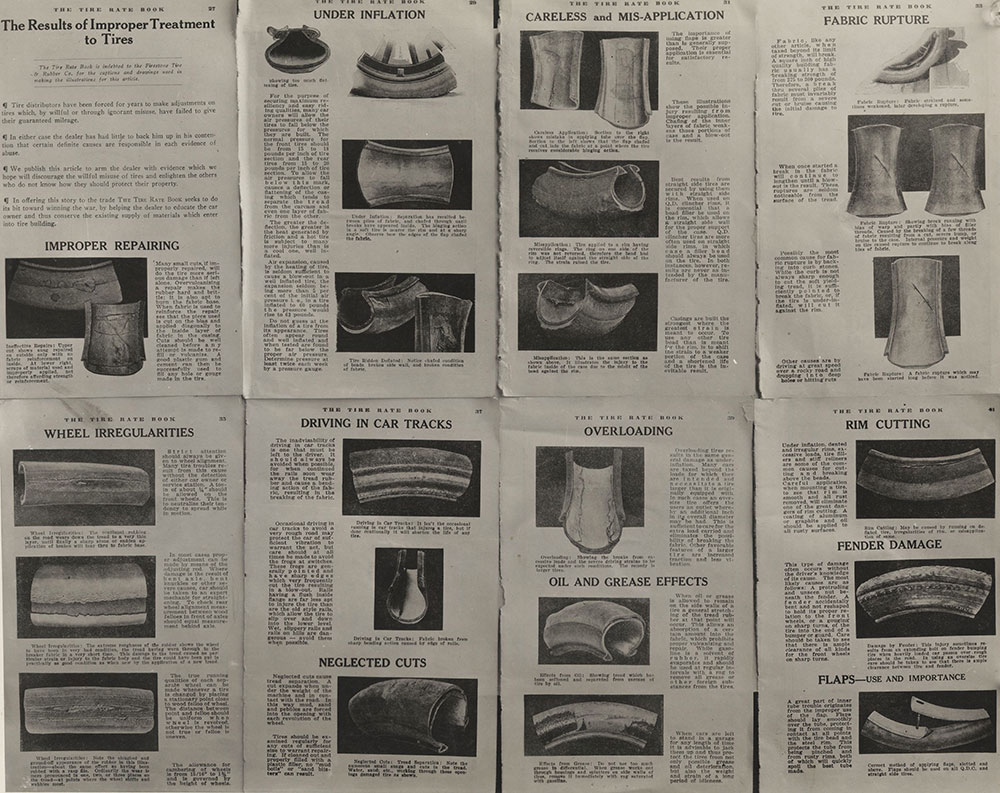

The Results of Improper Treatment to Tires

The Tire Rate Book is indebted to the Firestone Tire & Rubber Co. for the captions and drawings used in making the illustrations for this article.

-Tire distributors have been forced for years to make adjustmentson tires which, by willful or through ignorant misuse, have failed to give their guaranteed mileage.

-In either case the dealer has had little to back him up in his contention that certain definite causes are responsible in each evidence of abuse.

-We publish this article to arm the dealer with evidence which we hope will discourage the willful misuse of tires and enlighten the others who do not know how they should protect their property.

-In offering this story to the trade The Tire Rate Book seeks to do its bit toward winning the war, by helping the dealer to educate the car owner and thus conserve the existing supply of materials which enter into tire building.

Improper Repairing

Many small cuts, if improperly repaired, will do the tire more serious damage than if left alone. Overvulcanizaing a repair makes the rubber hard and brittle; it is also apt to burn the fabric base. When fabric is used to reinforce the repair. See that the piece used is cut on the bias and applied diagonally to the inside layer of fabric in the casing. Cuts should be well cleaned before any attempt is made to refill or vulcanize. A good plastic gum and cement can then be successfully used to fill any hole or gouge made in the tire.

(photo caption): Ineffective Repairs: Upper cut shows snag repaired on outside only with no fabric reinforcement on inside. At lower right, scraps of material used and improperly applied, not therefore affording strength or reinforcement.

p. 29

Under Inflation

For the purpose of securing maximum resiliency and easy riding qualities, many car owners will allow the air pressures of their tires to fall below the pressures for which they are built. The normal pressure for the front tires should be from 15 to 18 pounds per inch of tire section and the rear tires from 15 to 20 pounds per inch of tire section. To allow the air pressures to fall below this mark, causes a deflection or flattening of the casing which tends to separate the tread from the carcass and even one layer of fabric from the other. The greater the deflection, the greater is the heat generated by friction and a hot tire is subject to many more injuries than is a cool one, well inflated. Air expansion, caused by the heating of tire, is seldom sufficient to cause a blow-out in a well inflated tire, the expansion seldom being more than 5 percent of the initial air pressure i.e., in a tire inflated to 60 pounds the pressure would rise to 63 pounds. Do not guess at the inflation of a tire from its appearance. Tires often appear round and well inflated and when tested are found to be far below the proper air pressure. Determine pressure at least twice each week by a pressure gauge.

(top photo caption): Showing too much flattening of tire.

(middle photo caption): Under Inflation: Separation has resulted between piles of fabric, and chafed through until breaks ahve appeared inside. The hinging action in a soft tire is nearer the rim and at a sharp angle. Observe how the edges of the flap chafed the fabric.

(bottom photo caption): Tire Ridden Deflated: Notice chafed condition of beads, broken side wall, wall, and broken condition of fabric.

p.31

Careless and Mis-Application

The importance of using flaps is greater than is generally supposed. Their proper application is essential for satisfactory results. These illustrations show the possible injury resulting from imporper application. Chafing of the inner layers of fabric weakens those portions of case and a blow-out is the result. Best results from straight side tires are secured by using them with straight side rims. When used on Q.D. clincher rims, it is essential that a bead filler be used on the rim, which allows a straight side wall for the proper support of the case. Q.D. clincher tires are more often used on straight side rims, in which case a filler bead should always be used on the tire. In both instances, however,results are never as intended by the manufacturer of the tire. Casings are built the strongest where the greatest strain is meant to occur. To use any other tire bead than is meant for the rim, is to shift the strain to a weaker portion of the case and a shortened life of the tire is the inevitable result.

(top photo caption): Careless Application: Section to the right shows mistake in applying tube over the flap. Section to the left shows that the flap chafed and cut into the fabric at a point where the tire receives considerable hinging action.

(middle photo caption): Misapplication: Tire applied to a rim having reversible rings. The ring on one side of teh rim was not reversed, therefore the bead had to adjust itself against the straight side of the ring. The strain ruined the tire.

(bottom photo caption): Misapplication: This is the same section as shown above. It illustrates the injury to the fabric inside of the case due to the misfit of the bead against the rim.

p. 33

Fabric Rupture

Fabric, like any other article, when taxed beyond its limit of strength, will break. A square inch of high quality building fabric usually has a breaking strength of from 275 to 300 pounds. Therefore, a break thru several plies of fabric must invariably result from a severe cut or bruise causing the initial damage to tire. When once started a break in the fabric will continue to lengthen until a blowout is the result. These ruptures are seldom noticeable from the surface of the tread. Possibly the most common cause for fabric rupture is by backing into curb stones. While the curb is not always sharp enough to cut the soft yielding tread,it is sufficiently pointed to break the fabric, or, if the tire under-inflated, will cut it against the rim. Other causes are by driving at great speed over a rocky road and dropping into deep holes or hitting ruts.

(top photo caption): Fabric Rupture: Fabric strained and sometimes weakened, later developing a rupture.

(middle photo caption): Fabric Rupture: Showing break running with bias of warp and partly with bias of filler threads. Caused by the breaking of a few threads of fabric resulting from a cut, severe bump, or bruise to the case. Internal pressure and weight on tire caused rupture to continue to break along bias of fabric.

(bottom photo caption): Fabric Rupture: A fabric rupture which may have been started long before it was noticed.

p.35

Wheel Irregularities

Strict attention should always be given to wheel alignment. Many tire troubles result from this cause without the detection of either car owner or service station. A toe-in of about 1/4'' should be allowed on the front wheels. This is to neutralize their tendency to spread while in motion. In most cases proper adjustment can be made by means of the adjusting rod. Where damage is the result of bent axle, bent knuckles or other severe causes, car should be taken to an expert mechanic for straightening. To check rear wheel alignment measurement between wood felloes in front of axles should equal measurement behind axle. The true running qualities of each separate wheel can be made whenever a tire changed by placing a stationary point close to wood felloe of wheel. The distance between point and felloe should be uniform when wheel is revolved, otherwise the wheel is not true or felloe is uneven. The allowance for cambering of wheels is from 15/16'' to 1 3/4'' and is governed by the height of wheels.

(top photo caption): Wheel Irregularities: The continual rubbing on the road wears down the tread to a very thin layer, until finally a sharp stone or sudden application of brakes will tear thru to fabric base.

(middle photo caption): Wheel Irregularities: The extreme roughness of rubber shows the wheel to have been in very bad condition, the tread having worn through to the breaker fabric in very short time. This damage to the tread caused no particular strain or injury to the fabric body and the tire could have been put in practically as good condition as when new by the application of a new tread.

(bottom photo caption): Wheel Irregularities: Note the sloughed and ground-off appearance of the rubber in this illustration--about the same effect as having been rubbed with a rasp file. Ordinarily the wear is more prounounced in one, two, or three places on the tread--at points where the wheel shifts and wabbles the most.

p. 37

Driving in Car Tracks

The inadvisability of driving in car tracks is one that must be left to the driver. It should always be avoided when possible, for when continued the rails soon wear away the tread rubber and cause a bending action of the fabric, resulting in the breaking of the fabric. Occasional driving in car tracks to avoid a very rough road may protect the car of sufficient vibration to warrant the act, but care should at all times be made to avoid the frogs at switches. These frogs are generally pointed and ahve sharp edges which very frequently cut the tire resulting in a blow-out. Rails having a flush inside flange are far less apt to injure the old style rails, which allow the tire to slip over down into the lower level. Wet, slipper rails and rails on hills are dangerous--avoid them when possible.

(top photo caption): Driving in Car Tracks: It isn't the occasional running in car tracks that injures a tire, but if done continually it will shorten the life of any tire.

(middle photo caption): Driving in Car Tracks: Fabric broken from sharp bending action caused by the edge of rails.

Neglected Cuts

Neglected cuts cause tread separation. A cut expands when under the weight of the machine and in contact with the road. In this way mud, sand and pebbles are forced

into the opening with each revolution of the wheel. Tires should be examined regularly for any cuts of sufficient size to warrant repairing. If cleaned out and properly filled with a plastic filler, no "mudd bolls" or "sand blisters" can result.

(bottom photo cpation): Neglected Cuts: Tread Separation: Not the numerous small snags and cuts in the tread. Water, sand, etc., working through these openings damaged tire as shown.

p. 39

Overloading

Overloading tires results in the same general damage as under-inflation. Many cars are taxed beyond the loads for which they are intended and necessitate a tire larger than it is originally equipped with. In such cases and overisze tire offers the users and outlet whereby an additional inch in its overall diameter may be had. This is sufficent to care for the extra load carried and eliminates the possibility of breaking the fabric. Other favorable features of a larger tire are increaed traction and less vibration.

(top photo caption): Overloading: Showing the breaks from excessive loads and the severe driving strains to be expected under such conditions. The remedy is larger tires.

Oil and Grease Effects

When oil or grease is allowed to remain on the side walls of a tire a general stretching of the tread rubber at that point will occur. This allows an absorption of a certain amount into the fabric, which prohibits proper vulcanizing and repair.

While gasoline is a solvent of rubber, it rapidly evaporates and should be used at regular intervals with a rag to remove all grease or other foreign substances from the tires.

When cars are left to stand in a garage for any length of time it is advisable to jack them up and thus protect the tires from not only possible grease and oil deterioration, but also the weight and strain of a long period of idlenes.

(middle photo caption): Effects from Oil: Showing tread which has been softened and separated from carcass of tire by oil.

(bottom photo caption): Effects from Grease: Do not use too much grease in differential. When grease works out through housings and splatters on side walls of tires, remove it immediately with rag saturated with gasoline.

p. 41

Rim Cutting

Under inflation, dented and irregular rims, excessive loads, tire fillers and stiff reliners are some of the common causes for cutting and breaking above the beads. Careful application when mounting a tire, to see tha trim is smooth and all rust removed, will eliminate one of the great dangers of rim cutting. A coating of aluminum or graphite and oil should be applied to all rusty surfaces.

(top photo caption): Rim Cutting: May be caused by running on deflated tire, irregularitiesof rim, or misapplication of same.

Fender Damage

This type of damage often occurs without the driver's knowledge of its cause. The most likely causes are as follows: A protruding and unseen nut beneath the fender. A fender accidentally bent and not reshaped to hold its proper relation to the front wheels, or a gouging on sharp turns, of hte tire into the end of a bumper or guard. Care should be taken to see that there is ample clearance of all kinds for the front wheels on sharp turns.

(middle photo caption): Damage by Fender: This injury sometimse results from an extending bolt on fender bumping tire when heavily loaded car passes over rough places in the road. In using an oversize tire care should be taken to see that there is ample clearance between tire and fender.

Flaps-Use and Importance

A great part of inner tube trouble originates from teh improper use of the flap.Flaps should lay smoothly over the tube, protecting it from coming in contact at all points with the tire bead and the steel rim. This protects the tube from being pinched and from rusty rims, both of which will quickly spoil the best tube made.

(bottom photo caption): Correct method of applying flaps, slotted end above. Flaps should be used on all Q.D.C. and straight side tires.

Tools

- Pan and Zoom

- Cite

- For a high-resolution copy of this image contact the AACA Library.